Mobile plant and equipment fires

This bulletin provides information to reduce to risk of uncontrolled fires occurring on mine sites.

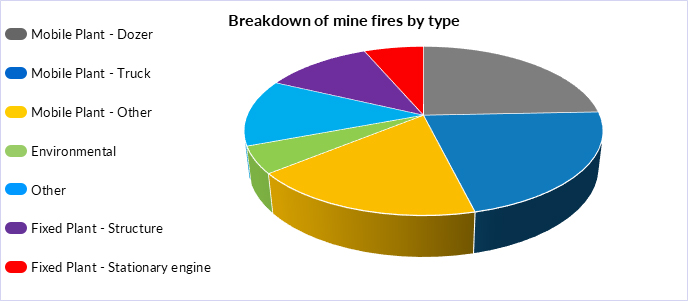

During the past 3 years (2020 to 2022) NT WorkSafe received in excess of 80 notifications of fires on Northern Territory mine sites. Over 65% of these fires are on mobile plant and equipment. The majority of the fires have been attributed to component failure such as hydraulic lines and/or inadequate maintenance.

Fire hazards present an unacceptable risk to workers, whether they be machine operators, first responders or maintenance crew. An improvement to the management of equipment fire hazards is required to reduce the risk to as low as reasonably practicable.

The most common reports are attributed to post maintenance failures including blown or leaky hoses, incorrect fittings, rubbing of hoses resulting in failures, exposure of hoses to hot surfaces, lack of shielding between hot pipes and pipework carrying fluids. These have all resulted in spraying of oils and fluids onto hot areas including overheated bearings, turbos and engine exhausts, often resulting in fire.

Many of these fires were detected by workers and controlled using hand held extinguishers or manually activating fire suppression systems. These systems are manual relying upon human intervention to be effective. While a control mechanism it is being relied upon too often and the main root causes are often ignored.

Fire is a critical risk in most industries and must be addressed through effective controls and effectiveness monitoring. Critical risk controls must be understood by all personnel and applied without exception to ensure everybody’s safety.

Major contributing factors which lead to fire

- Inadequate scope and/or scheduling of maintenance and inspection of vehicles and plant

- Quality of regular maintenance (i.e. over-greasing, incorrect grease type , not cleaning oil and grease from surfaces)

- Quality of inspections on critical items (i.e. missing rubbing hoses)

- Failure to identify defects or act on defects within an adequate timeframe (i.e. waited too long to rectify)

- Quality/integrity of pressurised fluid containing lines (i.e. wrong type of oil or grease used)

- Non-Original Equipment Manufacturer (OEM) hoses and fittings that do not properly fit

- Hydraulic oil contact with hot engine areas (i.e. lines failed and too close to hot components)

- Poor maintenance leading to a build-up of combustible material (lubricant and fuels) near heat or ignition sources (i.e. bearings overheating)

- Ineffective isolation of ignition sources such as battery terminals.

Strategies

To reduce the number of fires, an improvement in the approach to managing maintenance and fires is needed, which requires a combination of protection and prevention measures.

In addition to current site strategies workplaces should consider the following.

Management strategies

- Analyse site fire reports to identify trends and improvement opportunities to minimise risk of fires

- Complete specific machine risk assessments and ignition hazard assessment for targeted equipment, high risk plant or where workers are exposed to a high risk of fire, to identify controls based on prevention as well as protection

- Use a change management process and sound engineering principles when fitting after-market, non-standard equipment to ensure components are correctly fitted and rated, compatible and protected

- Ensure all equipment coming to site, including contractor equipment, meets site fire prevention standards

- Consider quality checks being conducted by third parties periodically as a cross check for internal maintenance

- Repeat this periodically to assess the outcome of initiatives and refine strategies

- Provide focused senior management commitment and appoint a champion to implement fire reduction strategy

- Involve site contractors and partners in the strategy development and implementation

- Involve OEMs in fire investigations and report equipment fires to the OEM

- Ensure all remediation actions as reported by OEMs bulletins are implemented.

- Consult with OEMs before making any changes to equipment.

Maintenance strategies

- During maintenance, clearly define and appropriately resource the scope of repair work, including ensuring that the people carrying out the work are appropriately competent to do this work. Clearly specify the standard to be met before equipment is returned to service

- Review turbo replacement strategies. Life cycle analysis should be undertaken to make sure a best for business replacement strategy has been adopted

- Consider replacing oil feed and drain lines, seals and lagging associated with the turbocharger when it is replaced, as heat affected lines which have been disturbed or oil soaked components often catch on fire after maintenance

- Consider alternate products such as approved, non-flammable coolants or higher temperature manufacturer approved hydraulic oils

- Consider proactive replacement strategies based on service life of critical components (e.g. hoses)

- Proactively monitor hydraulic hoses including checks on connections, clamps, and pressure relief valves

- Use thermal imaging equipment to detect hot spots and high temperature areas of plant during maintenance programs

- Systematically inspect all components in the hydraulic and other oil systems during routine parts replacement

- Areas affected by flammables such as fuel, oil and some coolants are thoroughly cleaned. Routinely wash, clean and check hoses for any sources of rubbing, oily mist or leaks

- Replace adjacent heat affected components such as hoses

- Consider targeted inspections of high risk components and installations. Photographs of the acceptable site standard of installation are beneficial

- Consider adopting a risk-based hydraulic hose management system.

A structured approach to fire reduction will lead to positive results.

What you should do

Recommended control measures to prevent similar incidents occurring include:

- Provide appropriate training to all mobile plant staff on hydraulic hazards, fire detection and response procedures

- Use manufacture recommended hoses and fittings designed and tested to fit correctly

- Systematic inspection of all components within a hydraulic or fuel supply circuit during routine part replacements

- Proactively monitoring of hydraulic hoses including checks on hose connections, clamps and pressure relief valves. Consider a dedicated, regular inspection (hose audit) that includes the inspection of the hard to get out/at, out of sight, hoses and connections

- Adopt a risk based hydraulic hose management system

- Verify internal maintenance systems with additional quality checks by manufacturers or authorised service providers

- Evaluate isolation techniques such as shielding for potential engine heat sources or insulation of hoses near hot components

- Routine inspection of electrical systems for corrosion or insulation fatigue

- Consider the location and rating of protective devices such as fuses and wiring control

- Install, maintain and systematically inspect fire detection and automatic fire suppression systems on vehicles or plant operating at a higher risk of fire

- Install fire detection and automatic fire suppression on all plant that is used in high risk zones and install engine auto-shutdown systems that operate when the fire suppression system is discharged

- Ensure communication of fire-related events, maintenance incidents and subsequent attendance and associated follow-up is clear to employees.

Further information

Safety alerts

- Vehicles and other mobile plant fires

- Maintenance and modifications causing fire risks in heavy vehicles and mobile plant

Australian standards

- AS 5062-2006 Fire Protection for Mobile and Transportable Equipment (Standards Australian)

- AS 5062:2016 Fire Protection Equipment (Standards Australian)

Guidance material

- Generation of flammable mists from high flashpoint fluids: Literature review (Health and Safety Executive (UK))

- Fires on mining equipment (WorkSafe New Zealand)

- Preventing fires on mobile plant, discussion paper (NSW Resources Regulator)

- In-services fires on mobile plant (NSW Resources Regulator)

- Equipment fires, investigation and response (Resources Safety & Health Queensland)

- Fires on mine sites (Resources Safety & Health Queensland)