Asbestos identified in Shantui Forklifts

The purpose of this Safety Alert is to provide information about the potential presence of asbestos in Shantui Forklifts imported from the People’s Republic of China (China).

Background

The identified forklifts were imported to Queensland in 2013 by a person conducting a business or undertaking (PCBU). Under statutory direction from Workplace Health and Safety Queensland the PCBU has subsequently removed the asbestos-containing components.

As these forklifts containing asbestos have been imported and supplied within Australia, the Rapid Response Protocol (RRP) has been initiated.

Product description

In 2019, WHSQ investigated asbestos in the Shantui Forklift battery insulation and in the engine and hydraulic system gaskets. Sample analysis results viewed as part of the investigation confirmed asbestos in the following Shantui branded forklifts, which were all imported to Australia from China in 2013:

- battery insulation and exhaust gaskets of 3-tonne forklifts

- exhaust gaskets of 5-tonne forklifts, and

- exhaust gaskets and the hydraulic tank gasket of 7-tonne forklifts.

3-tonne Shantui Forklifts

5-tonne Shantui Forklifts

7-tonne Shantui Forklifts

Asbestos in imported products

While asbestos has been prohibited in Australia since December 2003, in some countries it is still used in manufactured products. Certification of asbestos-free goods from some overseas manufacturers have been found not to meet Australian requirements. The importation, manufacture, supply, sale and use or reuse of asbestos and asbestos-containing products is not permitted, except under very limited circumstances. Some supplier countries may classify goods with low levels of asbestos as ‘asbestos-free’. In Australia, any level of asbestos is prohibited for import or use.

Risk control

Analysis of the battery insulation material and the gaskets identified fibres of chrysotile asbestos. The fibres are bonded to other material. Any risk from asbestos depends on the extent of asbestos fibre release and inhalation of these fibres, which can be caused by damage to the materials.

As the asbestos fibres are bonded to other material it does not pose a measurable health risk through normal use. However, over time the materials may become damaged through wear and tear resulting in the asbestos fibres being less bonded. Therefore, you should not perform any maintenance, repairs or modifications on these parts as this may lead to asbestos contaminated dust being released. Compressed air should also not be used on or in vicinity to these materials.

Action required

Under the Northern Territory Work Health and Safety (National Uniform Legislation) Regulations 2011, it is unlawful for a PCBU to use or supply a product with asbestos if imported after the 31 December 2003, such as renting out affected forklifts.

1. Battery compartment of your 3-tonne Shantui forklift

It is recommended that users and owners of the forklifts inspect the battery compartment of the 3-tonne Shantui forklift for the presence of fibrous battery insulation material. If found, the forklifts should be isolated from use and a competent person trained in the identification and safe handling of asbestos (for example a Certified Occupational Hygienist, Licensed Asbestos Assessor or Licenced Asbestos Removalist) should be engaged to have a sample of the material analysed for the presence of asbestos.

If asbestos is confirmed within the battery heat insulation material, a competent person (Licenced Asbestos Removalist) trained in the safe handling and application of suitable controls measures for carrying out asbestos-related work should be engaged to remove the asbestos material in accordance with the Code of Practice – How to manage and control asbestos in the workplace.

It is also recommended that a clearance certificate be obtained from a competent person after removal. Consultation should be held with the forklift manufacture regarding a replacement heat insulation material.

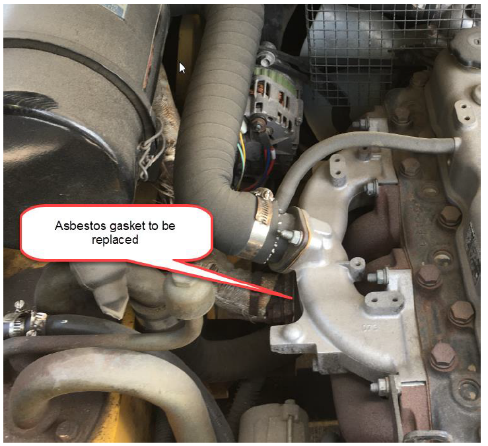

2. Engine exhaust gaskets and hydraulic seal

The identified gaskets of the Shantui 3-tonne, 5-tonne and 7-tonne forklifts should be assumed to contain asbestos. Components identified with asbestos must only be removed by a person who is competent to do so safely. Appendix E of the SWA code of practice provides an example of a “working with asbestos friction materials” safe work method that can be used, including appropriate personal protective equipment, decontamination and disposal of the asbestos waste.

Spare gasket materials of the same brand should also be assumed to contain asbestos unless testing confirms no asbestos is present. Alternatively, the spare gaskets can be disposed of as regulated waste and replaced with gaskets that are certified as asbestos free in accordance with Australian requirements.

3. Assess other forklifts for presence of asbestos containing gaskets

Although the testing results only confirm the presence of asbestos in these specific components, it is recommended that owners of imported forklifts generally assess for asbestos in other gaskets or components designed to resist heat. Sampling and accredited testing should be seen as a viable method for the assessment of suspect components.

Further information

For further information, please refer to the following:

Guidance

- Northern Territory asbestos awareness website

- Importing, exporting and manufacturing prohibited goods (Australian Border Force)

- NT Environmental Protection Authority

Codes of Practice

Disclaimer

This Safety Alert contains information developed by the Heads of Workplace Safety Authorities (HWSA) Imported Materials with Asbestos Working Group as part of the Rapid Response Protocol into the identification of chrysotile asbestos in Shantui forklifts.

The information contained in this Alert does not necessarily include the outcome of the HWSA action with respect to an incident. NT WorkSafe does not warrant the information in this Alert is complete or up-to-date and does not accept any liability for the information in this report or as to its use.