Ride failure highlights the need for rigorous inspection and testing of amusement rides

The purpose of this safety alert is to highlight the risk of serious injury or death if amusement rides or devices are not inspected and tested to the appropriate standard.

Background

A sweep support rod on an amusement ride known as The Octopus broke, causing the corresponding sweep arm to buckle at the Fred’s Pass Show in May 2019. The ride took two revolutions before coming to a stop, whereby the gondola attached to the arm of the ride, carrying two adult patrons crashed to the ground.

A structural condition report, which included a welding inspection report, was commissioned as part of the NT WorkSafe investigation.

During setup at a separate community event the following month, NT WorkSafe issued an improvement notice on a Swinging Chair Ride owned by a different company, requiring the reinspection by a competent person. Non-destructive testing (NDT) conducted as part of the inspection found cracks in the main shaft of the ride.

Contributing factors included:

- The Octopus sweep arm that buckled showed signs of previous welded repair work in two locations along its length, possibly affecting the structural integrity.

- The break point of the sweep support rod showed signs of corrosion, indicating there were two cracks in the rod before the incident.

- Magnetic particle testing showed the welds and rod ends for all 8 sweep support rods were defective.

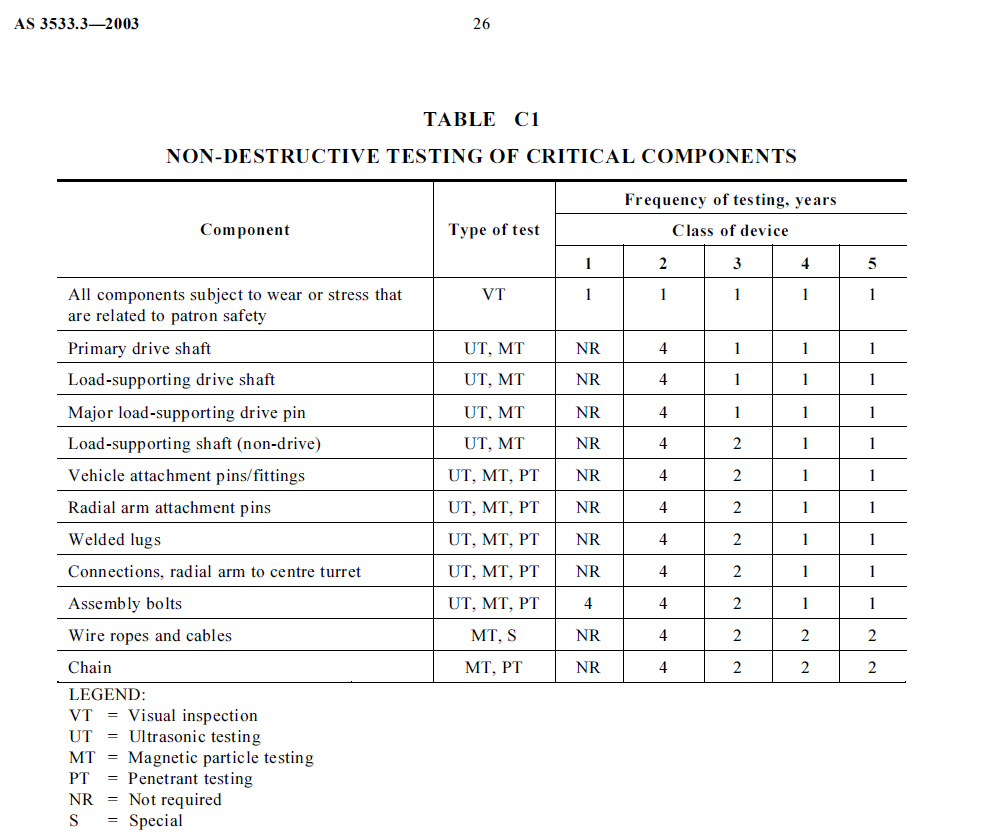

- An audit of the records for both amusement devices indicate NDT may not have been conducted at the frequency required under the Australian Standards for that class of device.

- NDT may not have been conducted on all critical components as required by Australian Standards.

- NDT (particular ultrasonic testing and magnetic particle testing) may not have been conducted on the welded connections and repair welds.

- An absence of a protective cover on the brake disc lead to contamination affecting the efficiency of the brake, which contributed in the ride performing two full revolutions before coming to a stop.

Action required

- Amusement device owners and operators must ensure that all rides are properly maintained as specified in the manufacturers operating manual, and a competent person carries out inspections and testing to the frequency required by Australian Standard AS 3533.3 as a minimum.

- Amusement device owners and operators must ensure that all welded repair work be tested in accordance with Australian Standard AS3533 and reinspected by a competent person prior to use.

- Certifying engineers must ensure that amusement devices are classified in the correct class of device in accordance with AS3533 Amusement Rides and Devices, including all inflatable devices.

- The correct classification will ensure the appropriate frequency of inspections and testing to maintain the safe operation of the amusement device.

- Amusement device owners and operators are reminded that an amusement device will require a major inspection as specified in Australian Standard AS3533.2. A major inspection is additional to the annual inspection and must be conducted in accordance with Australian Standard AS3533.3.

Further considerations

- Ensure bolted joints have thread-locking devices and washers with a minimum of one full thread visible above the nut after tightening (AS4100 Clause 14.3.6.1), noting, however, that best practice for structural bolts or high risk items is generally regarded as 2.5 to 3.0 threads past the nut after tightening. When high tensile bolts are required, a nut of corresponding grade or property class and a high tensile washer shall be used.

- Ride restraints to be in accordance with Appendix G of AS3533.

Further information

For further information, please refer to the following.

Australian Standards

- Australian Standards AS3533 series – Amusement rides and devices.

Guidance publications (Safe Work Australia)

Disclaimer

This Safety Alert contains safety information following inquires made by NT WorkSafe about an incident or unsafe practice. The information contained in this Alert does not necessarily include the outcome of NT WorkSafe’s action with respect to an incident. NT WorkSafe does not warrant the information in this Alert is complete or up-to-date and does not accept any liability for the information in this report or as to its use.