Securely restrain excavator buckets and attachments before transportation

The purpose of this Safety Alert is to highlight common industry practice of transporting excavator attachments in a large excavator bucket, and the risk associated with the attachments dislodging and causing serious injury if not securely restrained.

Background

In April 2019, a 30-year-old worker was fatally injured while loading an excavator onto a float in the yard of a hire company. At the time of the incident, the excavator was fitted with a batter bucket carrying two smaller buckets and a single tine ripper. The attachments were not secured before the excavator was maneuvered onto the float for transportation.

During final positioning of the excavator onto the float, one of the smaller buckets dislodged from the batter bucket and struck the worker who had come onto the float deck while the operator was still positioning the excavator.

Contributing factors included

- Storing and transporting smaller attachments in the larger bucket unsecured is a widespread industry practice, and it is common to see smaller attachments preloaded in the larger buckets ready for hire.

- The attachments were not secured to the batter bucket before the excavator was maneuvered onto the float.

- There was no policy or procedure at the hire yard for customers to pick up and transport hired equipment.

Action required

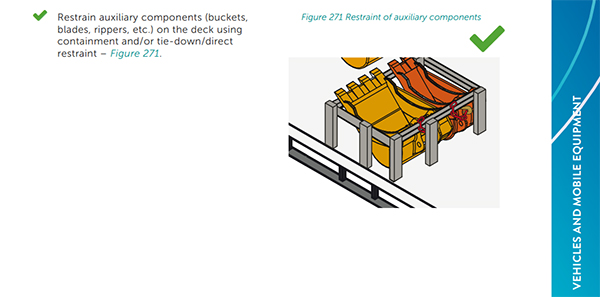

- Mobile plant attachments should be restrained on the deck of the float as outlined in the Load Restraint Guide 2018 (see image below).

- If smaller attachments are being transported in a larger bucket, these attachments must be securely restrained to the bucket carrying them.

- Before operating any mobile plant, the operator and any workers must establish a system of communication before any work starts, this system should:

- Stop workers from approaching the mobile plant until the operator has established visual contact and has signalled that it is safe to approach.

- If an operator has signalled a worker to approach, the operator should stop the equipment, put it in a safe mode, and take their hands off the controls.

- If the operator loses sight of the worker, they should stop operations until they re-establish visual contact with the worker.

- Workers should never approach mobile plant and assume that the operator can see them.

- Workers should never stand under or near a suspended load in case of equipment malfunction or operator error.

Further information

For further information please refer to the following:

Code of practice

Guidance publications

- Load Restraint Guide 2018 (National Transport Commission)

Disclaimer

This Safety Alert contains safety information following inquires made by NT WorkSafe about an incident or unsafe practice. The information contained in this Alert does not necessarily include the outcome of NT WorkSafe’s action with respect to an incident. NT WorkSafe does not warrant the information in this Alert is complete or up-to-date and does not accept any liability for the information in this report or as to its use.