Work health and safety requirements for Solar PV installers

This bulletin outlines the work health and safety requirements for Solar PV installers under the Work Health and Safety (National Uniform Legislation) Act 2011.

Solar PV Installation considered High Risk Construction Work

Regulation 289(2)(e) of the Work Health and Safety (National Uniform Legislation) Regulations 2011 defines the meaning of construction work, which includes the installation, testing or maintenance of an essential service in relation to a structure.

The installation, testing, or maintenance of solar panels is considered the installation of an essential service (electricity) and is therefore considered to be construction work. This means that a safe work method statement (SWMS) must be prepared for the work.

Solar PV installers may do the following work, which is considered high-risk construction work under the Regulations:

- Work involving a risk of a person falling more than 2 metres (e.g. installing Solar PV panels on a roof).

- Work carried out or near energised electrical installations or services (e.g. installing Solar PV panels near the overhead service line or working in the ceiling space near the cables supplying the switchboard).

- Work carried out in an area at a workplace in which there is any movement of powered mobile plant (e.g. using a crane or scissor-lift to move equipment onto the roof).

- Work carried out in an area in which there are artificial extremes of temperature (e.g. working in the ceiling space to connect the supply cables to the inverter unit).

Regulation 291 provides the full list of high-risk construction work activities.

The business installing the Solar PV system must prepare a safe work method statement (SWMS)—or ensure a SWMS has been prepared—before any high-risk construction work starts.

What is a safe work method statement?

A SWMS is a written document that helps the business, supervisors and workers implement and monitor the control measures established at the workplace to ensure high-risk construction work is carried out safely.

A SWMS must identify and document:

- the high risk construction work activities to be carried out at a workplace;

- the hazards and risks to health and safety associated with these activities;

- the measures to be implemented to control the risks; and

- how the control measures are to be implemented, monitored and reviewed.

Further information on completing a Safe Work Method Statements is in the Construction work – Code of Practice.

The person responsible for carrying out the high-risk construction work is best placed to prepare the SWMS in consultation with workers who will be directly engaged in the high-risk construction work. Working through the risk management process will provide the information needed for the SWMS.

Make the SWMS available

The SWMS must be readily accessible to any person carrying out the high-risk construction work and for inspection by a WorkSafe Inspector. The SWMS must be kept until the high-risk construction work it was prepared for is completed, or for at least 2 years if a notifiable incident occurred during the high-risk construction work.

If you revise a SWMS, every version should be kept.

The risk management process

The risk management process is a systematic process where you think about what could go wrong at the worksite and what the consequences could be. Then you must do whatever you can (in other words, whatever is ‘reasonably practicable’) to eliminate or minimise health and safety risks arising from your work activities.

The How to manage work health and safety risks – Code of Practice details the following four steps in the risk management process:

- Identify hazards

Find out what could cause harm to people. - Assess the risk

Understand the nature of the harm, how serious is can be and likelihood of it happening. This step might not be necessary if you are dealing with a known risk with known controls. - Control the risk

Implement the most effective control measure that is reasonably practicable in the circumstances and ensure it remains effective over time. - Review the control measures

Review the hazards and control measures to make sure they are working as planned.

Two important elements that need to occur during each step is management commitment to safety and consultation with your workers. If there are other tradies working at the worksite, you all need to consult with each other and coordinate your work activities.

Common hazards for Solar PV installation

Identifying and understanding the hazards in the workplace is the important first step in completing a SWMS. The following are some common hazards faced by Solar PV installers.

-

Working on the roof

- Falls from heights – either from open edges of the roof or through fragile sections of roofing, such as skylights, or tripping when moving from one level to another (e.g. from the ladder to the roof).

- Hit by falling objects – dislodged or unsecured objects or tools falling and hitting workers below.

- Electrocution and fire – Damaged solar panels or short circuits in the array wiring create a risk of electrocution and fire when the panels generate electricity when exposed to sunlight.

- Accidental contact with an overhead service line is also an electrocution risk.

- Heat stress – exposure to the sun combined with the radiant heat from the roof increases the risk of heat stress for workers on the roof.

- Asbestos exposure – Older buildings built before the 1990’s are likely to contain asbestos. Eaves and switchboard panels are a common location for asbestos in the Northern Territory.

-

Working in the ceiling

- Heat stress – radiant heat from the roof increases the temperature inside the enclosed ceiling space.

- Electrocution – rodents and other pests can damage electrical wiring in the ceiling space. Electrical wiring supplying the switchboard are live unless the property is disconnected. Supply cables from the solar panels to the inverter unit will be live when the solar panels are generating electricity.

- Sharp objects - protruding screws and nails in roof trusses and ceiling joists.

- Venomous creatures – snakes, spiders or other stinging insects can be found in the ceiling space.

- Asbestos exposure – Many buildings in the Northern Territory are likely to contain asbestos. Common areas Asbestos is can be found may include ceiling, eaves and switchboards.

- Exposure to pest control products distributed throughout the ceiling space.

-

Working on the ground

- Hit by falling objects – dislodged or unsecured objects or tools falling from the roof.

- Slips and falls from unsecured ladders.

- Hit by mobile plant – mobile plants such as cranes or elevated work platforms colliding with workers.

- Asbestos exposure.

It is important that you identify all the hazards at each specific worksite when you prepare your SWMS, rather than rely on a generic SWMS that covers the high-risk work activities your workers normally do.

Example: Some hazards might be unique to a specific worksite, such as an old house still having an asbestos roof. The SWMS in this example will need to detail the measures to control the risk of asbestos exposure.

If access to the ceiling space cannot be avoided.

Regulation 128 and 129 of the Electrical Safety Regulations 2024.

Work performed in a roof space of a Class 1 building, Class 2 building or Class 10 building must not be undertaken until the building's electrical installation is de-energised by a competent person.

Tradespersons should ensure that all sources of electricity supply to the premises are isolated before entry to the ceiling space.

- This may include the identification and isolation of all sources of electricity supply to the premises by a Licensed Electrical Contractor.

- If there is another source of power connected to the house, such as a solar panel or generator, this must also be isolated before accessing the ceiling space.

- Simply turning off all main switches at the switchboard/s may not isolate all sources of electricity supply to the premises.

Control measures

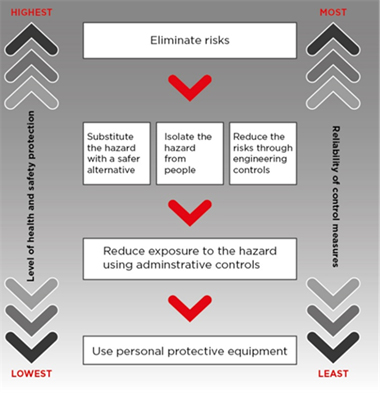

Starting at the top of the hierarchy, you must always try to eliminate the risk, as this is the most effective control. If it is not reasonably practicable to eliminate the risk, you must minimise the risk by working through the alternatives in the hierarchy.

You can combine a number of different control measures together if you feel it provides the highest level of protection for your workers. Check the regulations to ensure that you have the right information as some specific hazards such as falls from height and asbestos have specific requirements.

Examples of using a combination of control measures

-

Example 1: Contact with energised wires in the ceiling space.

To reduce the risk a company might introduce the following control measures:

- Isolate all power at the switchboard before accessing the ceiling space (eliminate);

- Lock out the main switch to prevent accidental energisation (engineering);

- Identify and avoid potentially energised cables, such as Solar PV and switchboard supply cables (administration); and

- Adequate hands free lighting (such as a head mounted torch or freestanding area light) that allows workers to safely move about in the ceiling space (personal protective equipment).

-

Example 2: Interaction between Forklift and workers.

Interaction between Forklift and workers is a common hazard in warehouses, which can cause serious crush injuries. To manage this risk, the following control measures may be introduced:

- Install reverse alarms and flashing lights on all forklifts (engineering);

- Paint designated walkways for workers to walk along (administrative); and

- Require all workers to wear high-vis vests (personal protective equipment).

Information about suitable controls for many common hazards and risks can be obtained from:

- Codes of Practice and Guides available on the NT WorkSafe website;

- The user manual or operation manual for any plant, equipment you use in the workplace, or

- Safety data sheet for chemicals

Further information on how to control risks is in the How to manage work health and safety risks – Code of Practice.