Body stressing main cause of injury

Body stressing is a collective term covering a broad range of health problems associated with repetitive and strenuous work. Typical body stressing injuries that occur at the workplace (commonly known as musculoskeletal disorders) include strains and sprains, back or neck injuries, and tendonitis/tenosynovitis.

Many workplaces require their workers to perform some kind of manual tasks (also known as manual handling) with their everyday job and in many cases, the manual tasks that are performed would be classified as hazardous manual tasks.

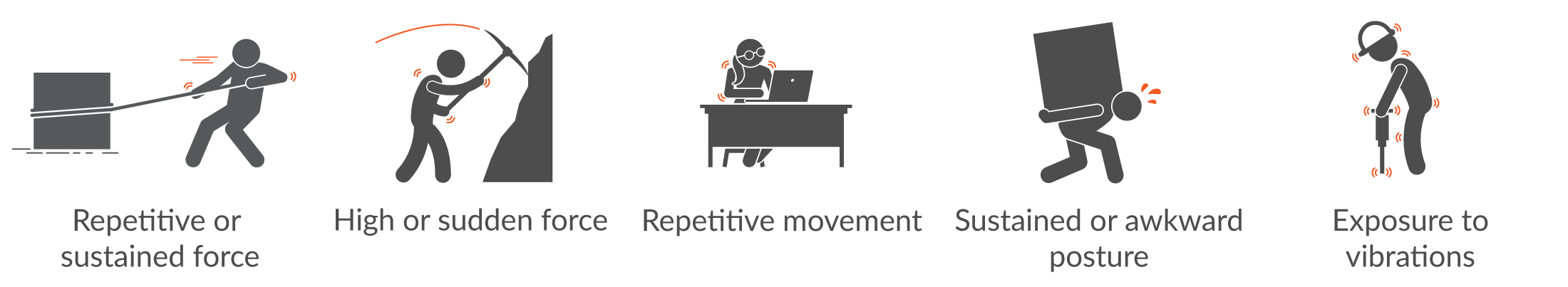

Hazardous manual tasks are the most common cause of workplace injuries and all businesses have a duty to manage them. A manual task becomes hazardous when one or more of the following risk factors are present:

These five factors are also known as the characteristics of a hazardous manual task.

Body stressing was the main mechanism of injury for workers’ compensation claims in 2019-20.

Over half (62.13%) of the serious injury claims for body stressing occurred in five industry sectors

Body stressing injuries affect all worker occupation types across all industry sectors.

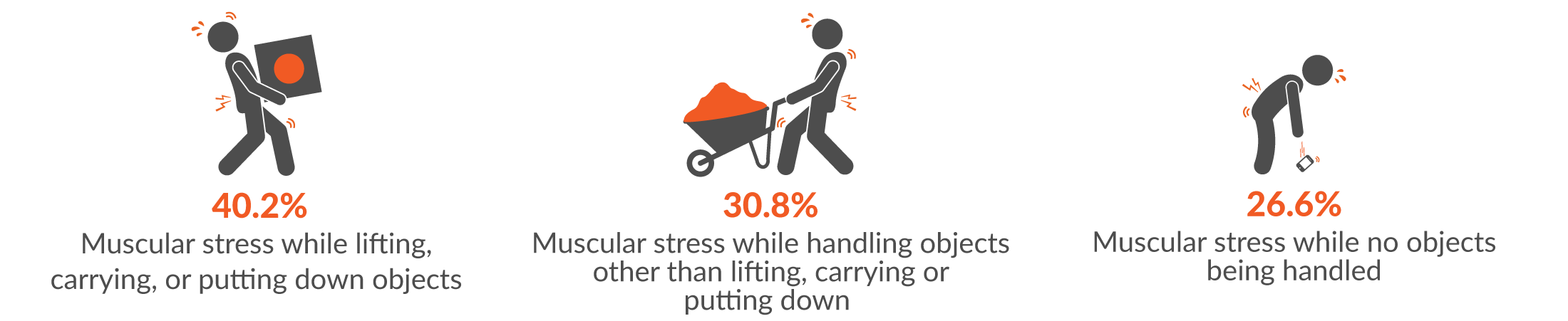

The majority (97.6%) of all serious injury claims for body stressing occurred as a result of the following three main incident types:

Safety Information

NT WorkSafe strongly urges all workplaces undertaking manual or hazardous tasks to ensure the following measures are in place, and that they are effective:

- Undertake Hazard Identification, Risk Assessment and Control (HIRAC) beginning by identifying hazards related to body stressing in the workplace using the Code of Practice for how to manage work health and safety risks;

- Consider available control measures and implement the control measures that most effectively eliminate or minimise the risks so far as is reasonably practicable. These can include:

- Providing mechanical aids to workers to assist in the safe movement of goods, persons or products. This could include pallet jacks, trolleys, winches and portable patient lifters. Ensure all equipment is maintained and repaired according to the manufacturer’s specifications.

- Lightening loads by separating them into smaller quantities wherever possible, or replace heavy items with those that are lighter, smaller or easier to handle.

- Breaking up repetitive work and allocate time for rest breaks.

- Providing appropriate personal protective equipment such as heat resistant gloves or shock absorbent shoes;

- Follow the Northern Territory’s Work health and safety consultation, cooperation and coordination Code of Practice, and consult your workers and their health and safety representatives when deciding how to manage the risks in the workplace, including when reviewing and making changes to existing processes;

- Discuss the hazards identified and the control measures you have implemented at your next toolbox talk or team meeting;

- Have systems in place which ensures all:

- Workers and duty holders have information about the hazards associated manual handling and hazardous tasks which enables them to fulfil their responsibilities in managing the risks in the workplace;

- Persons in the workplace have appropriate training and instructions necessary to protect them from risks to their health and safety associated with manual handling or hazardous tasks.

Further information

- NT WorkSafe code of practice for Hazardous Manual Tasks

- SafeWork SA - Manual Handling

- Complete the Manual Tasks (NSW) checklist

- Safe Work Australia: