Incorrect installation increases risk of DC isolator fires

The purpose of this Safety Alert is to warn Solar PV installers and electrical contractors of the increased risks of fires if DC isolators are not installed correctly and in line with manufacturers’ guidelines.

Background

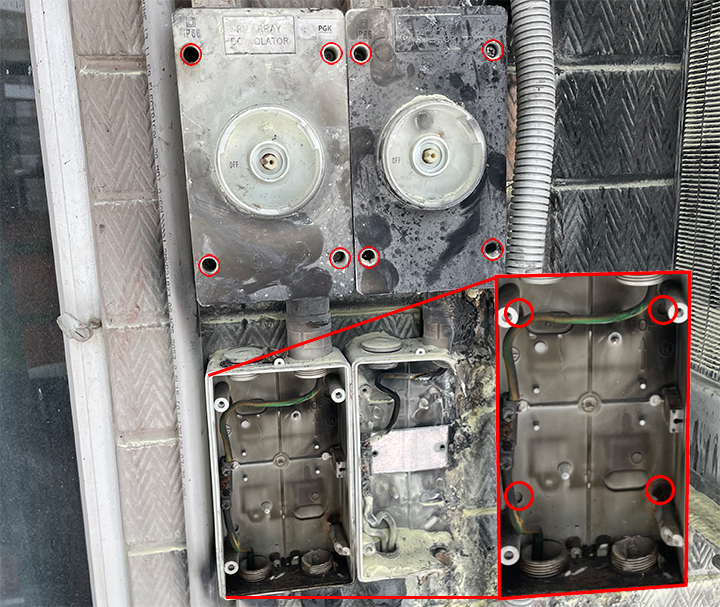

Electrical Safety Inspectors have attended eight fires DC isolator fires this year, with two fires causing extensive damage to the property. Half the fires occurred at commercial properties and the other half at residential properties. All eight DC isolators had been installed outdoors.

DC isolator casings are manufactured with ingress protection (IP) and incorrect installation can compromise the IP allowing dust and moisture to enter the isolator casing, increasing the risk of fire.

Possible contributing factors

- The DC Isolators were installed by drilling through the mounting holes at the back of the case, which is only meant for indoor installations only.

- Not all capping plugs were placed over the screws to seal the isolator properly.

- The isolator cover may not have been secured evenly to maintain IP.

- The upper and/or lower sealing caps may not have been correctly tightened after the cables were connected.

Action required

- Check that the brand of isolator you are installing hasn’t been recalled by either the Clean Energy Council (CEC) or Product Safety Australia.

- Install DC isolators in accordance with the AS/NZS 3000:2018 Amendments 1, 2 & 3, AS/NZS 5033:2021, CEC guidelines and the manufacturer’s instructions.

- In line with the CEC guidelines, an accredited installer is required to stay onsite to either undertake or supervise the installation.

- When installing DC Isolators outdoors, always use the mounting brackets supplied.

- Only drill through the mounting holes at the back of the case if the installation manual indicates this option is suitable for outdoor installation, and always secure capping plugs over the screws as per the installation manual.

- If the installation manual advises to use sealant, ensure the sealant selected is suitable for the installation location, and is installed to the manufacturers requirements.

- After screwing on the isolator cover, ensure all sides of the cover and base are level and secure before sealing the screws with the capping plugs.

- Ensure all both upper and lower sealing caps are tightened after the cables are connected.

Building certification requirements

Solar PV Installers are reminded that building certification is required for all installations in areas of the Northern Territory that may be impacted by a cyclone. There is no exemption to this requirement. Additional information is available in the bulletin Certification requirements for installing Photo Voltaic (PV) Panels on buildings.

Installations in non-cyclonic areas require a competent person to write a declaration that the roof structure is suitable for the installation of solar panels, please refer to the Building Advisory Committee policy Installation of Photovoltaic Panels in non-cyclonic regions of the NT (BAC/2011/001).

Further information

For further information, please refer to the following:

Safety Alert

Guidance information

- Certification requirements for installing Photo Voltaic (PV) Panels on buildings

- Clean Energy Council accreditation guidelines

- Installation of Photovoltaic Panels in non-cyclonic regions of the NT (BAC/2011/001)

Australian Standards

Disclaimer

This Safety Alert contains safety information following inquires made by NT WorkSafe about an incident or unsafe practice. The information contained in this Alert does not necessarily include the outcome of NT WorkSafe’s action with respect to an incident. NT WorkSafe does not warrant the information in this Alert is complete or up-to-date and does not accept any liability for the information in this report or as to its use.